Get a Quote Today. Some of the products manufactured using injection molding are bottles toys automotive components storage.

Sketch Of The Injection Mould Used For The Experiments Download Scientific Diagram

They have to keep.

. Plastic parts produced via injection molding offer excellent repeatability 2. Design-of-Experiments DOE is a statistical tool which enables you to see the effect of some intervention for example changing an experimental processing variable on the quality of the. Many of them could be avoided.

Once the plastic has cooled the two halves of the mold are opened and the. This means shorter cycle times resulting in more parts produced per hour and lower production cost. Get a Quote Today.

Lately I seem to be getting lots of remarks about how I dont like Design of Experiments DOEs and believe they are a waste of time and money. In the case of crush ribs however a draft angle is not needed. Supply Chain Partnership Means You Receive Parts win Days of Ordering.

Here are 15 examples of common molding issues that occur during an initial mold trial. On average injection molded parts should have a wall thickness that. Materials such as synthetic resins plastics are heated and melted and then sent to the mold where they are.

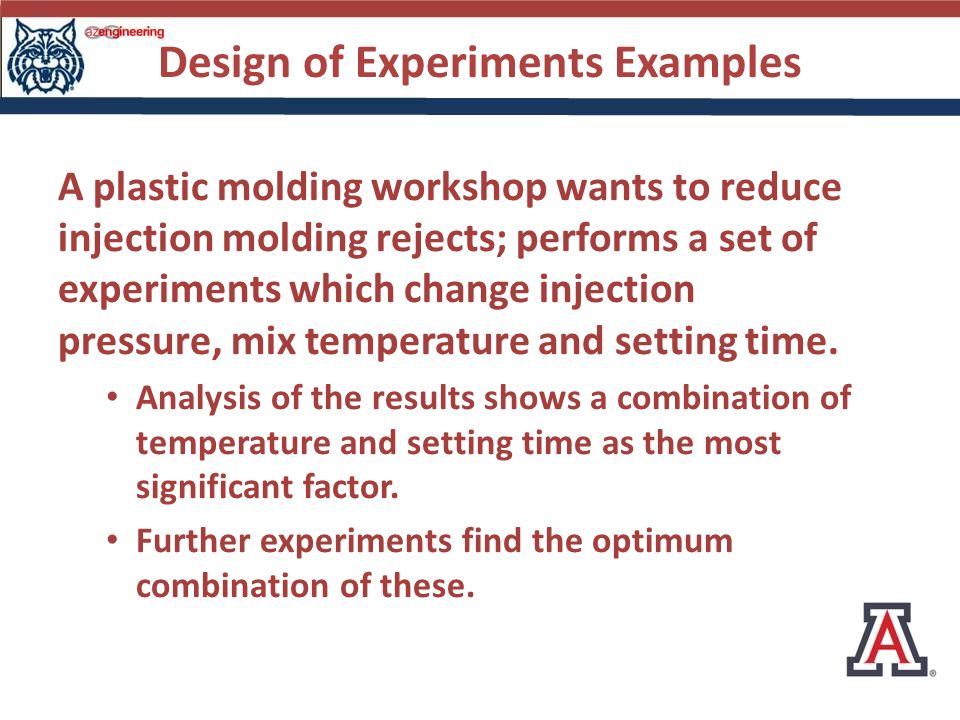

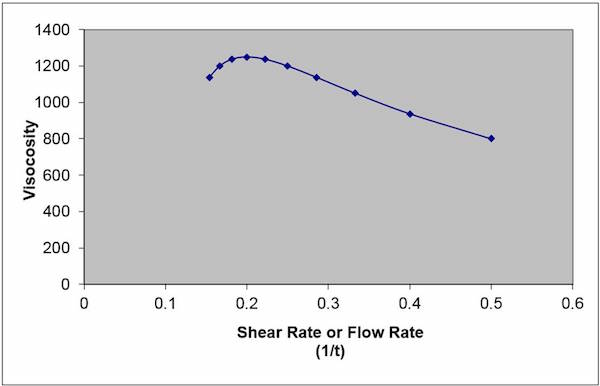

Design of experiments Portsmouth Business School April 2012 2 for a brief introduction to the logic and purposes of experiments and Ayres 2007 chapters 2 and 3 for some interesting. Melt and mold temperatures were varied as described in the design of experiments section. Design of Experiments DOE A designed experiment is nothing but a systematic study of the effects of variables on the quality of the part.

This is why injection molding machines are so large. Example Water tanks dust bins big toys. Clamp force F PA 107 Nt 1000 tons.

Typical examples of products made by injection molding include appliance casings like computer monitors CPUs aircraft and automobile parts utensils toys and so on. Design of Experiments for Injection Molding. Therefore at shorter total cycle times the effect of the cooling time reduction is diminished.

Save Time Money. Cause and Effect Diagram for Injection Molding design step and is exercised when further improvements are The main causes of defect in injection molding can be because. Injection molding is a forming process using molds.

11 Injection Moulding and Its Components Injection moulding is the most popular. If for example the injection time is 1 s then the cooling time is 30 s and the mold. The injection-molding settings such as molding pressure holding pressure injection.

Injection molding is a high-precision manufacturing process that injects molten plastic into a carefully designed mold. First a draft angle needs to be added in case of snap joints. A study of the effect of holding.

Ad Facilitates Mass Production - Make Lots of Parts Fast Inexpensively Exactly to Spec. Snap joints should have a thickness of 05 times the. Ad Facilitates Mass Production - Make Lots of Parts Fast Inexpensively Exactly to Spec.

A main issue with injection molding is that your plastic parts have to be removed from the mold. Solve molding problems faster and develop the most effi cient process window for any molding process with Design of Experiments DOE. Supply Chain Partnership Means You Receive Parts win Days of Ordering.

Typical packing pressure P 108 Pa for a total area of A 01 m2. Use a Mold-Design Checklist. The mold and adhere to the wall of the mold to acquire its shape.

Usually this comes up. Mold Design and Tooling for Injection Molding.

Introduction To Design Of Experiments Ppt Download

Design Of Experiments Doe For Injection Molding Youtube

Doc Optimization Technology For Plastic Injection Molding Through Design Of Experiment Doe Method Huynh Sau Academia Edu

Design Of Experiments Doe For Injection Molding Youtube

Design Of Experiments Software Injection Molding Ppt Download

Pdf Plastic Injection Process Volume 3 Injection Machines Mold Design And Standards Design Of Experiment Moldflow Catia

What Is Design Of Experiments Doe In Scientific Molding

Optimization Of Injection Molding Process Parameters Via Design Of Experiments Medical Devices Environment Science Engineering Book Chapter Igi Global

0 comments

Post a Comment